CHAPTER ONE

INTRODUCTION

Most of the rural Indian families

depend heavily on biomass to meet their household cooking energy requirements. Fuel

wood often accounts for a major fraction of the total biomass use. Fuel wood is

generally preferred to non-wood biomass residues due to its higher energy

density and convenience in use and transportation. Large quantities of biomass

residues are available in India. These include rice husk, rice straw, wheat

straw, corncob, coconut shell, bagasse, and many other agricultural residues.

The residues are normally difficult to use, particularly in small-scale

systems, due to their uneven and troublesome characteristics. Although biomass

offers itself as a sustainable and carbon-neutral source of energy, its

inefficient use in household cooking results in wastage, indoor air pollution

and related respiratory and other health problems. Excessive use of fuel wood

is also exerting pressure on the region’s forest cover. Although large quantities

of surplus biomass residues are available in India, due to certain difficulties

experienced in using them in the traditional cooking devices, their use has

been severely restricted. The non-availability of suitable cost-effective

technologies for utilizing biomass residues for household cooking has resulted

in gross under utilization and neglect of biomass residues as a potential

energy source in this sector.

However, energy from biomass can be efficiently

used by means of gasifier stoves. Many different types of gasifier stoves have

been designed and constructed so far and they are showing good performance too.

Wood

gas cook stove developed by Thomas Reed and Ron Larson[1], Charcoal making wood

gas cook stove developed by Elsen Carstad[2], IISc gasifier stove by Indian

Institute Of Science[3], San San rice husk gasifier stove developed by U Tin

Win[4] and many others have led to an efficient harnessing of biomass energy.

Gasification is the process that

converts carbonaceous materials such as coal, petroleum, biofuel, or biomass

into carbon monoxide and hydrogen by reacting the raw materials, such as house

waste, or compost at high temperatures with a controlled amount of oxygen and/or

steam. The resulting gas mixture is called synthesis gas or syngas and is

itself a fuel. Gasification is a method for extraction of energy from many

different types of organic materials.

Pyrolysis is a form of

incineration that chemically decomposes organic materials by heat in the

absence of oxygen. Pyrolysis typically occurs under pressure and at operating

temperatures above 430 °C (800 °F). In practice, it is not possible to achieve

a completely oxygen-free atmosphere. As some oxygen is present in any pyrolysis

system, a small amount of oxidation occurs. The word is coined from the Greek-

derived elements, pyre meaning “fire” and lysis meaning “loosening”.

1.1 Biomass as

an energy source for cooking in Asia:

Domestic cooking accounts for the

major share of the total biomass use for energy in Asia. However, use of

biomass fuels in traditional stoves is characterised by low efficiency and

emission of pollutants. In an effort to address these problems, many of the

Asian countries have initiated national programs to promote improved cook

stoves. Although significant achievements have been reported in some of these

countries, the potential for further efficiency improvements is still very

large. A study by Bhattacharya et al[7] estimated that the biomass saving potential

in seven Asian countries (China, India, Pakistan, Nepal, Philippines, Sri Lanka

and Vietnam) as 152 million tons of fuel wood and 101 million tons of

agricultural residues, in the domestic cooking sector alone in early nineties.

The amount of biomass that can be saved through efficiency improvement can

serve as a source of additional energy and can potentially substitute for

fossil fuels to reduce net GHG emission. With the escalating costs of fossil

fuels and gas as a preferred cooking fuel (than fuel wood, residues, kerosene

etc.), biomass gasifiers are attracting renewed interest. The possibilities for

biomass gasification technology for cooking applications are leading to a

number of initiatives to demonstrate the potential benefits of introducing them

in developing countries. Wider use of the gasifiers stoves in developing

countries could save on cooking fuel costs, improve the reliability of fuel

supply by making rural communities more self-reliant and improve indoor air

quality. Gasifier-based cooking systems have some very attractive features,

i.e., high efficiency, smoke free clean combustion, uniform and steady flame,

ease of flame control, and possible attention-free operation over extended

duration. While these make them an attractive choice in the kitchens of the

developing world, there are cost and technology barriers which limit their

wider adoption.

1.2 Difference between gasifier stoves

and conventional stoves:

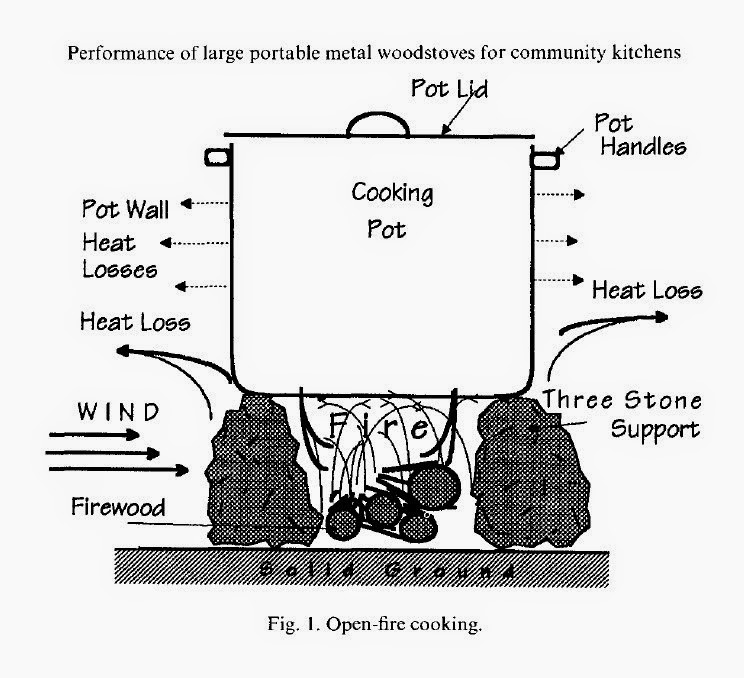

Apart

from being fuel efficient, gasifier stoves are also emission efficient in

comparison to traditional cook stoves. The traditional cook stoves, because of

their very low efficiency, emit more than 10% of their carbon as products of

incomplete combustion (PIC) comprising varying amount of tars. In addition,

about 100-180 g of carbon monoxide and 7.7 g of particulate matter are also

emitted per kg of wood. Gases such as methane, total non-methane organic

compounds (TNMOC) and N2 O are added to this. These PIC emissions

are even higher in the case of loose biomass or cow dung used as fuel in these

stoves. Some of the natural draft stoves (based on combustion of gas produced

from biomass) developed so far are listed in Table 1. The capacity of these

stoves ranges from 3kWth to 20kWth, making them suitable for domestic as well

as community cooking applications. Compared to the 5-15% efficiency of

traditional cook stoves in the Asian region, the efficiency of these gasifier

stoves is in the range of 25-35%.

1.3 History:

The

gasification process was originally developed in the 1800s to produce town gas

for lighting and cooking. Electricity and natural gas later replaced town gas

for these applications, but the gasification process has been utilized for the

production of synthetic chemicals and fuels since the 1920s. Wood gas

generators, called Gasogene or Gazogène, were used to power motor

vehicles in Europe during World War II fuel shortages.

Four

types of gasifier are currently available for commercial use:

1.3.1. The counter-current fixed bed ("up draft") gasifier: It consists of a fixed bed

of carbonaceous fuel (e.g. coal or biomass) through which the

"gasification agent" (steam, oxygen and/or air) flows in

counter-current configuration. The ash is either removed dry or as a slag. The

slagging gasifiers have a lower ratio of steam to carbon , achieving temperatures higher than the ash

fusion temperature. The nature of the gasifier means that the fuel must have

high mechanical strength and must ideally be non-caking so that it will form a

permeable bed, although recent developments have reduced these restrictions to

some extent. The throughput for this type of gasifier is relatively low.

Thermal efficiency is high as the gas exit temperatures are relatively low.

However, this means that tar and methane production is significant at typical

operation temperatures, so product gas must be extensively cleaned before use.

The tar can be recycled to the reactor.

1.3.2. The co-current fixed bed ("down draft") gasifier: It is similar to the counter-current type,

but the gasification agent gas flows in co-current configuration with the fuel

(downwards, hence the name "down draft gasifier"). Heat needs to be

added to the upper part of the bed, either by combusting small amounts of the

fuel or from external heat sources. The produced gas leaves the gasifier at a

high temperature, and most of this heat is often transferred to the

gasification agent added in the top of the bed, resulting in energy efficiency

on level with the counter-current type. Since all tars must pass through a hot

bed of char in this configuration, tar levels are much lower than the

counter-current type.

1.3.3. The fluidized bed reactor: Here, the fuel

is fluidized in oxygen and steam or air. The ash is removed dry or as heavy

agglomerates that defluidize. The temperatures are relatively low in dry ash

gasifiers, so the fuel must be highly reactive; low-grade coals are

particularly suitable. The agglomerating gasifiers have slightly higher

temperatures, and are suitable for higher rank coals. Fuel throughput is higher

than for the fixed bed, but not as high as for the entrained flow gasifier. The

conversion efficiency can be rather low due to elutriation of carbonaceous

material. Recycle or subsequent combustion of solids can be used to increase

conversion. Fluidized bed gasifiers are most useful for fuels that form highly

corrosive ash that would damage the walls of slagging gasifiers. Biomass fuels

generally contain high levels of corrosive ash.

1.3.4. The entrained flow gasifier: Here, a

dry pulverized solid, an atomized liquid fuel or a fuel slurry is gasified with

oxygen (much less frequent: air) in co-current flow. The gasification reactions

take place in a dense cloud of very fine particles. Most coals are suitable for

this type of gasifier because of the high operating temperatures and because

the coal particles are well separated from one another. The high temperatures

and pressures also mean that a higher throughput can be achieved; however

thermal efficiency is somewhat lower as the gas must be cooled before it can be

cleaned with existing technology. The high temperatures also mean that tar and

methane are not present in the product gas; however the oxygen requirement is

higher than for the other types of gasifiers. All entrained flow gasifiers

remove the major part of the ash as a slag as the operating temperature is well

above the ash fusion temperature. A smaller fraction of the ash is produced

either as a very fine dry fly ash or as a black colored fly ash slurry. Some

fuels, in particular certain types of biomasses, can form slag that is

corrosive for ceramic inner walls that serve to protect the gasifier outer

wall. However some entrained bed type of gasifiers do not possess a ceramic

inner wall but have an inner water or steam cooled wall covered with partially

solidified slag. These types of gasifiers do not suffer from corrosive slags.

Some fuels have ashes with very high ash fusion temperatures. In this case

mostly limestone is mixed with the fuel prior to gasification. Addition of a

little limestone will usually suffice for the lowering the fusion temperatures.

The fuel particles must be much smaller than for other types of gasifiers. This

means the fuel must be pulverized, which requires somewhat more energy than for

the other types of gasifiers.

1.4. Natural vs Forced convection

1.4.1.

Natural convection: provides poor mixing of air with fuel

gases and can result in incomplete combustion, soot and emissions in open wood

stoves. A chimney can supply 1 mm water pressure per meter of height. Addition

of a chimney for cooking can greatly improve wood combustion in closed models,

but also adds complication and requires wasting heat to operate[7].

1.4.2.

Forced convection: provides good mixing and combustion for

gas cooking and is widely used in homes and camping stoves. The 3 W blower used

in the Turbo Stove provides 7.5 mm water pressure and makes clean cooking

possible[7].

CHAPTER TWO

OBJECTIVE

AND SCOPE

2.1. Objective

of the work

The basic aim of

the project is to design a gas stove working on biomass energy for domestic use

that is cheaper, cleaner and more efficient than the conventional cooking

methods used in rural areas. Therefore the objectives of our work are:

2.1.1.

To design a gasifier stove for domestic purpose.

2.1.2.

To construct the stove using locally available materials.

2.1.3.

To carries out experimentations to evaluate the performance of the stove.

2.2. Scope

2.2.1. Study of existing designs of producer gas stoves.

2.2.2. Carry out comparison of different existing designs.

2.2.3. Selection of a particular design and carry out study for

modifications of the design to fit into our local conditions.

2.2.4. Selection of locally available cheap materials for practical

implementation of the design.

2.2.5. Construction of the designed gas stove.

2.2.6. Experimentation to evaluate efficiency of the stove.

CHAPTER

THREE

METHODOLOGY

3.1. Chemistry

of Gasification

In

a gasifier, the carbonaceous material undergoes several different processes:

1.

The pyrolysis (or de-volatilization) process occurs as the carbonaceous

particle heats up. Volatiles are released and char is produced, resulting in up

to 70% weight loss for coal. The process is

Figure 3.1: Pyrolysis of carbonaceous fuel

Figure 3.2: Gasification of char

dependent

on the properties of the carbonaceous material and determines the structure and

composition of the char, which will then undergo gasification reactions.

2.

The combustion process occurs as the volatile products and some of the

char reacts with oxygen to form carbon dioxide and carbon monoxide, which

provides heat for the subsequent gasification reactions. Letting C represent

a carbon-containing organic compound, the basic reaction here is

C

+ 1/2O2 = CO2

3.

The gasification process occurs as the char reacts with carbon dioxide

and steam to produce carbon monoxide and hydrogen, via the reaction,

C + H2O = H2 + CO

4. In addition, the reversible gas phase water

gas shift reaction reaches equilibrium very fast at the temperatures in a

gasifier. This balances the concentrations of carbon monoxide, steam, carbon

dioxide and hydrogen.

H2O + CO = CO2 + H2

In essence, a limited amount of oxygen or air

is introduced into the reactor to allow some of the organic material to be

"burned" to produce carbon monoxide and energy, which drives a second

reaction that converts further organic material to hydrogen and additional

carbon dioxide. Further reactions occur when the formed carbon monoxide and

residual water from the organic material react to form methane and excess

carbon dioxide. This third reaction occurs more abundantly in reactors that

increase the residence time of the reactive gases and organic materials, as

well as heat and pressure. Catalysts are used in more sophisticated reactors to

improve reaction rates, thus moving the system closer to the reaction

equilibrium for a fixed residence time.

Gasifier-based

cooking systems have some very attractive features, i.e., high efficiency,

smoke free clean combustion, uniform and steady flame, ease of flame control,

and possible attention-free operation over extended duration. While these make

them an attractive choice in the kitchens of the developing world, there are

cost and technology barriers which limit their wider adoption.

3.2. Safety Measures to follow:

Producer gas was the only gas fuel

widely available until 1940 when natural gas pipelines became common. Since

producer gas contains 10-30% CO, it is a real health hazard if the flame is

extinguished or incomplete combustion occurs [8]. (Smoky open fires and

insufficient cooking fuel are also major health hazards in the world today.)

Therefore it is necessary to mandate good practice in using the Producer Gas

Stove. In the volatile combustion mode CO is a minor hazard because if the

flame should go out, the copious smoke warns the operator to re-ignite the fire

or move the stove outside. However, in the charcoal combustion mode the CO is

odorless and could pose a health hazard. It is recommended that all stoves

including the Producer Gas Stove should be operated under a hood carrying the

cooking odors and possible stove emissions to the outside by natural or forced

convection. That is the practice in most kitchens in developing countries today

and should be followed as the rest of the world develops.

3.3.

Producer Gas Stove Emissions:

Producer-gas cooking has very low

emissions and can be operated indoors with proper precautions once established

[9]. However, if the fire is extinguished for any reason the production of

smoke and CO continues, so that it is important to be able to extinguish it

completely or take

it

outside. The stove is difficult to extinguish but can be done by closing the

primary air supply at the bottom and outer cylinder side. During gasification

of wood, if the fire is extinguished the acrid tars in the wood make it

unlikely that one would breathe too much CO. However, after the wood is

gasified the stove contains hot charcoal and so can be a major source of CO.

For this reason it is important to either continue to burn the charcoal or to

cut off all air to the stove.

3.4. Study of existing stoves and search

for a suitable design:

i.

The Wood-Gas Cook Stove of Reed and Larson

use small wood chips and sticks for operation, and produce very low CO

emission, and hence suitable for indoor cooking. The rate of gas production can

be controlled by controlling the primary air supply to the gasifier. The

gasifier produces charcoal as a by-product [1].

ii.

Elsen Karstad’s Charcoal Making Wood Gas

Cooking Stove is a simple stove developed for the East African households [2].

Figure 3.4: Elsen Karstad's Charcoal Making Wood-Gas

Cook Stove

iii.

The Holey Briquette Gasifier Stove

developed by Stanley and Venter (2003) operates using a single biomass

briquette with a central hole (typically produced in extrusion type briquetting

machines) placed in the middle of the combustion/gasification chamber. At about

1.1 kW power, the stove offers efficiency of up to 35%[5].

PROTOTYPE OF BRIQUETTE GASIFYING STOVE

Figure 3.5: Holey Briquette

Gasifier Stove developed by Stanley and Venter

(1.1kW power; 35% efficiency).

iv. The IISc Gasifier

Stove can be operated using small wood sticks and pelletised waste, and has a

thermal output of 3-4 kW. Offering a water-boiling efficiency of 25-35%, the

stove can operate continuously for about 2 hours for a single fuel loading.

Emission from the stove has been found to be low[3] .

Figure 3.6: IISc’s Gasifier Stove

v.

The San San Rice husk Gasifier Stove

developed in Myanmar offers smokeless combustion ofrice husk in an efficient

manner. Gasification can be improved by mixing kitchen wastes suchas potato

peels, green leaves and fresh biomass, chopped into half inch pieces, with the

rice husk[4].

Figure 3.7: San San rice husk gasifier stove

developed in Myanmar

vi.

The three models of gasifier stoves developed

at AIT (Institutional Gasifier Stove/IGS2, Domestic Gasifier Stove/DGS2 and

Commercial Gasifier Stove/CGS3) operate on cross-draft principle, using wood

chips, wood twigs, coconut shells and ricehusk/sawdust briquettes as fuel

(Figures 6 and 7). Water-boiling efficiency is in the range of 22-31%,

depending on the type of stove and fuel used. Combustion is clean and steady,

and no tending is generally required during operation[6].

Figure 3.8: Institutional Gasifier Stove

IGS2 Figure 3.9: Commercial Gasifier Stove CGS3

developed at AIT

developed at AIT

(5.5 kW; 29% efficiency with

woodchips) (11.5 kW; 31% efficiency with

woodchips)

vii. Wood gas stove developed by College of

Engineering and Technology, Maharana Pratap University of Agriculture and Technology,

Udaipur, Rajasthan India, which has a capacity of 5 kw and works on natural

draft gasification mode[7].

Figure 3.10: Wood gas stove.

3.5. Methodology of production of our design:

Modification of presently available stoves

We

have designed a producer gas stove working on natural draft + inverted

downdraft gasification mode. For our design we took references from the

following natural draft gasifier stoves developed.

i.

Primary

air mechanism: primary air is the air which is

utilized in the initial burning of the biomass fed to the stove. Instead of

providing separate inlets for air and fuel feed, we have used a sliding door

for both entry of primary air as well as feeding biomass. Amount of air can be

controlled by sliding the door.

ii.

Ash

removal mechanism: a separate hollow

cylindrical shell is fitted at the bottom of the stove. The ash produced due to

the burning of biomass falls from the grate and gets collected in this shell.

The shell can be removed to discard the wastes and then refitted to the stove

easily for use again.

iii.

Secondary

air control: this is the air which helps in

the proper burning of the producer gas generated in the stove thereby producing

the flame. Minute holes along the periphery of the top part of the cylinder are

provided for the purpose.

iv.

Producer

gas outlet: very small holes, about seven to eight

in number, are provided at the top of the small cylinder over the main reactor

of the stove for the producer gas to come out and get burned to produce the

flame.

v.

Calculation

of critical radius of insulation: This is

calculated with the knowledge of thermal conductivity of fire clay brick(k),

the convective heat transfer coefficient between air and fire clay brick(h) and

finally applying the formula to calculate critical radius of insulation(rc);

which is, rc=k/h. Now the radius of insulation provided in the stove

must be greater than the critical value so as to minimize heat loss to the

surrounding. By Studying all the above stoves we have designed a producer gas

stove which works on the natural draft gasification mode and the design is

prepared considering the availability of the materials.

rc

= 1/8 = .125m = 12.5cm

where,

k = 1W/mK , h = 8W/m2K

By

Studying all the above stoves we have designed a producer gas stove which works

on the natural draft gasification mode and the design is prepared considering

the availability of materials and fuels in rural areas.

Figure 3.11: Solid works design of the producer gas

stove.

3.6. Construction:

·

Construction

of the stove have been done using

locally available materials which are listed below

|

Serial No.

|

Part of stove

|

Material used

|

|

1.

2.

3.

4.

5.

6.

7.

8.

|

Reactor Core

Grate

Insulation

Reactor outer cover

Biomass feeding door cum primary air

inlet

Removable portion at the bottom

Upper portion for combustion of the

producer gas

Tripod stand

|

Galvanized Steel

Galvanized Steel

Normal Crushed Brick

Galvanized Steel

Galvanized Steel

Galvanized Steel

Galvanized Steel

Mild Steel flattened bar

|

Table 3.1

The whole unit has been constructed in our college

workshop. The various shop we used for construction are Fitting shop, Welding

Shop, Carpentry Shop, Blacksmith Shop etc.

3.6.1. Construction Procedure:

·

Construction of the

Reactor Core: A

hollow galvanized steel cylinder of diameter 21cm, height 44cm having a grate

inside and a feed door on the body forms the main reactor core inside which

pyrolysis leading to the formation of producer gas takes place.

Figure 3.12: Reactor

core

· a) Construction of the

Grate: it is made by cutting a number of longitudinal slots on a galvanized

steel plate having diameter same as that of the internal diameter of the

reactor core. It is then welded at a suitable height above the bottom of the

core.

Figure 3.13: Grate

· b) Cutting primary air

inlet cum fuel feeding door on the reactor core the door dimensions (8×12cm)

are first marked on the body of the core on the outside and carefully cut out using

a chisel and hammer.

Figure 3.14: Primary

Inlet

· d) Preparation of

insulating material: A stainless steel sheet having lap joint surrounds the

core. The space between the core and the stainless steel cylinder is filled

completely with crushed normal brick which acts as a very good insulating

material.

· e) Construction of Reactor

Outer Cover: A stainless steel sheet is bent in the form of a cylinder and is

fixed by lap joints having a diameter of 38 cm.

Figure 3.15: Insulation

cover

·

Construction of upper portion

of the Reactor: A small cylinder of diameter 10.16cm of galvanized

steel is welded to the top of the core and there are holes on the top sheet for

the gas to come out.

Figure 3.16: Reactor

upper potion

· g) Construction of lower

portion of the Reactor: a circular sheet of the same material as the core is

slide fitted at the bottom for removal of ash that falls from the grate fitted

above.

· h) The tripod stand has

been constructed using MS flattened bars and it is basically for holding the

pot during cooking.

· i) Assembly: All the above

mentioned parts are assembled to get the stove. Below is the Stove with

different parts of it.

3.6.2. Structural Modification of the Design:

After construction of

the stove, we tried to fire it by feeding dry wood and coke but due to

deficiency in our design it did not work as expected. Therefore the seven

semester design has been modified in the present semester by consulting our

guide, and the whole modified design with its mechanisms is given below.

Figure 3.17: Modified Design

3.6.3.

Construction of modified design:

- The number of secondary

inlet holes has been increased for better generation of the cooking flame.

- The holes in the top portion of the stove have been replaced by a LPG burner for getting a uniform and intense flame.

CHAPTER FOUR

EXPERIMENTATION

4.1.

Experimental set-up and procedure

The

efficiency of a stove is usually defined as the ratio of heat transferred to

the cooking medium to heat supplied by fuel. The stove efficiency could be

evaluated by a number of standard methods such as Constant Heat Output Method,

Constant Temperature Rise Method, Constant Time Method, and [10]Water Boiling

Test (Prasad and Verhaart, 1983). Of these, the Water Boiling Test appears to

be most commonly used and this very test method is used in the performance

evaluation of our producer gas stove as well. The test is designed as a simple

method with which stoves made in different places and for different cooking

applications can be compared through a standardized and replicable test.

However,

the WBT also has weaknesses. In order to be applicable to many different types

of stoves, the WBT is only a rough approximation of actual cooking. Therefore,

the efficiency of the stove as found out by WBT will vary when the stove will

be subjected to real cooking.

In

a Water Boiling Test, a known quantity of water is heated on the cookstove. No

lid is used to cover the vessel so that evaporated water freely escapes from

the vessel. The quantity of water evaporated after complete burning of the fuel

is determined. Also the quantity of fuel burnt is found out by measuring the

amount of fuel left unburnt inside the reactor core.

4.1.1. Apparatus

for water boiling test:

1. A pan without lid.

2. Thermometer for measuring the ambient and

boiling

water temperature.

3. A balance for measuring the weight of fuel,

water

and pan.

4.1.2. Procedure

The

fuel and pan to be used in the test were separately weighed. The pan was

partially filled up with water and weighed again. The initial temperature of

water was recorded. The stove was ignited to initiate heating of the pan. After

letting the heating process to continue for about one hour and thirty minutes the

burning coal in the reactor core was put off and the process of heating was

thus terminated. The unburnt fuel, i.e., unburnt wood pieces were taken out and

weighed in order to find out the amount of fuel actually exhausted during the

test. The temperature to which water was heated was also recorded. The

calorific value of dry wood was taken from standard table.

All

these values are then put in the formula shown above in order to find out the

efficiency of the stove. The efficiency thus found out was the theoretical

efficiency of the designed stove. However, the actual performance of the stove

may vary to some extent when used for real cooking.

The

efficiency of the stove is calculated by using the following formula:

where,

mw,i

= initial mass of water in the cooking vessel, kg

=6 kg

cp,w

= specific heat of the water, kJ/kg°C

=4.2 KJ/ kg °C

mw,evap

= mass of water evaporated, kg

=0.3 kg

mf

= mass of fuel burned

=0.55 kg

Te

= temperature of boiling water, °C

= 100 °C

Ti

= initial temperature of water, °C

=29 °C

Hl

= latent heat of evaporation at 100°C and 105 Pa, kJ/kg

= 2257 KJ/kg

Hf

= Calorific value of fuel, kJ/kg

= 17400 KJ/ kg

Ƞ =

= 25.77%

4.2. Comparisons of the performance of

different gasifier stoves:

|

Sl no.

|

Name of the stove

|

Efficiencies

|

|

1

|

Briquette gasifying stove, by

Thomas Reed and Ron Larson.

|

35%

|

|

2

|

Institutional gasifier stove,

AIT.

|

29%

|

|

3

|

Domestic gasifier stove, AIT.

|

25%

|

|

4

|

Commercial gasifier stove, AIT.

|

31%

|

|

5

|

San San rice husk gasifier

stove, by U Tin Win.

|

29%

|

|

6

|

Charcoal making wood gas cook

stove, by Elsen Carstad.

|

30%

|

Table 4.1

The

efficiency of our stove is 25.77% due to availability of limited scope during

construction. A better performance can be achieved from the stove by using

still better and precise tool and techniques for construction of the same.

Figure 4.1: Producer gas stove in

operation

Figure 4.2: Evaporation of water due to tremendous heat formation

CHAPTER FIVE

CONCLUSION

We have come up with a new design

which is economically viable for rural households by studying some of the

existing designs. Several modifications have been made in the construction of

the producer gas stove which is necessary for getting much higher performance.

All the materials utilized in the construction of the stove are locally

available and cheap. This type of stove has the potential to save fuel wood

because it can work on a great variety of non-wood or waste-wood fuels. Improvements in household’s biomass burning stoves

potentially bring three kinds of benefits, i.e. reduced fuel demand, with

economic and time saving benefits to the household and increase sustainability

of the natural resources base; reduced

human exposure to health damaging air pollutants; and reduced emission of the greenhouse gases that

are contributing towards global climate change.

REFERENCES

Research Papers:

[1]T. B. Reed

and Ronal Larson. A wood-gas stove for

developing countries. Presented at the “Developments in Thermochemical

Biomass Conversion” Conference,Banff, Canada, 20-24 May, 1996.

[2]Karstad,

Elsen., 1997. Elsen Karstad's Charcoal Making Wood Gas Cooking Stove (Sept 97).

http://www.ikweb.com/enuff/public_html/ELK.htm

[3] IPOBIS.,

2004. Portable Wood/Biomass Stoves. Combustion, Gasification and Propulsion

Laboratory,

Indian Institute of Science, Bangalore. http://cgpl.iisc.ernet.in/stv_final.pdf

[4] SSIC, 2005.

San San Industrial Cooperative., Ltd., Myanmar. Accessed 20 Feb 2005.

http://www.benergyssic.com/sansanrice.htm.

[5]Stanley,

Richard., and Venter, Kobus., 2003. Holey Briquette Gasifier Stove Development.

Aug.2003. http://www.repp.org/discussiongroups/resources/stoves/Stanley/BriqGassstove.htm.

[6]N.L.Panwar,N.S.Rathore.Design

and performance evaluation of a 5kW producer gas stove.

BIOMASS AND BIOENERGY 32 (2008)1349–1352. Published by

Science Direct online on 27 May 2008.

[7]Bhattacharya

SC, Attalage RA, Augustus M. Potential of biomass fuel conservation in selected

Asian country. Energy Conversion and Management 2001(40):1141–62.

[8]Josef

Ayoub, Eric Brunet. Performance of large portable metal woodstoves for

community kitchens. Renewable Energy, Vol. 7, No. 1, pp. 71 80, 1996.Copyright

© 1996 Elsevier Science Ltd.

[9]T. B.

Reeda,b, E. Anselmoa and K. Kircherc1.Testing

& modeling the wood-gas turbo stove. Presented at the Progresss in Thermochemical Biomass

Conversion Conference, Sept.17-22, 2000, Tyrol, Austria.

Collected from Google Scholar.

[10]S.C. Bhattacharya, A.H. Md. M. R. Siddique, M. Augustus Leon, H-L.

Pham and C.P.Mahandari. A study on improved institutional biomass stoves.Energy Program,

Asian Institute of Technology, P. O. Box 4, Klong Luang, Pathumthani, Thailand.

Websites:

www.wikipedia.org

www.google.com/google scholar

www.sciencedirect.com